Meeting Topic

Introduction

By now, nearly everyone has become familiar with the term ‘AML’ or anti-money-laundering. Either your business has to report certain information about your new clients (you are a ‘reporting entity’) or you’ve been on the receiving end of AML identity verification. It’s all about managing risk in business, and the article below is meant to help us ALL understand the concept of risk regardless of whether we are considered a ‘reporting entity’ or not! Have a think about the potential financial risks in your business and what measures you’ve taken to manage those when you share your 1-minute intro next meeting.

Risk Management for Businesses by Dr Giulia Dondoli

Reporting entities in New Zealand must assess their money laundering risks, which means that they need to understand how their services can be exploited by money launderers, in the absence of any mitigation strategies. These risks are affected by several factors: the size and complexity of the reporting entity (big and complex organisations may have limited visibility on clients and transactions), the services offered (some services are more prone to favour anonymity than others), jurisdictional exposure, and so on. As an anti-money laundering consultant, I help my clients in assessing their money laundering risks and in developing adequate policies and procedures to mitigate such risks.

However, risk management principles apply to all aspects of business, and, whether consciously or unconsciously, we may often think about what we do in terms of risks. This post discusses how we can conceptualise risk and make informed decisions on risk management.

What is risk?

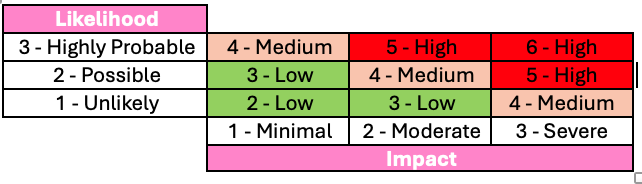

Risk is defined as the relationship between likelihood and impact. Likelihood is the possibility of a potential risk occurring. Impact is the expected harm or adverse effect due to exposure to such risk. With a simple likelihood-to-impact matrix, we can calculate a risk score by adding the value assigned to likelihood (from 1 to 3) to the value assigned to impact (also from 1 to 3).

For instance, the likelihood of spilling a drink in the kitchen can be rated as ‘Possible’, which we assigned a numerical value of 2. Meanwhile, the impact can be considered ‘Minimal’ since it only takes a few minutes to clean up, corresponding to a numerical value of 1. This results in a total risk score of 3, making drinking coffee a low-risk activity.

In our day-to-day lives, we may not need to use a risk matrix to assess risks. However, deconstructing risk between likelihood and impact can be a useful way to conceptualise risks when we need to make important decisions, like making an investment for our business, launching a new product or taking up a loan.

Once we have assessed risks, the next step is managing them.

Risk Management

We can use four key risk management strategies:

- Avoid – The best way to manage any risk is to avoid it. I consider skydiving an extremely high-risk activity, and I chose to avoid it. However, this is not always possible or advisable.

- Reduce – Our next best option is to reduce risk, by modifying our behaviour. I wear a seat belt while travelling in a car.

- Transfer – We can also transfer our risk to a different entity. I am concerned for my family in the case of an illness; therefore, I take a life insurance policy to transfer some of my risks.

- Tolerate – If we are not able (or willing) to do any of the above, the last remaining strategy is tolerating the risk.

These strategies do not exist in isolation, and they can be applied in combination with one another.

For more information on how Giulia supports her clients with anti-money laundering compliance, you can reach her at:

M: 021 0859 0042

Next Meeting Topic

Introduction

Ever heard of ‘LEAN’? Think it applies just to large production or manufacturing businesses? Well, read on and find out how you can apply relevant LEAN concepts to YOUR business! Because small tweaks in a few areas can yield big efficiency gains and less wasted time and money.

Spring Cleaning is a Year-Round Event! By Amber McNamara

“Lean” and “Continuous Improvement” methodologies are normally referred to in a manufacturing sense, but it can be applied anywhere, anytime. Lean methodology was first introduced by Taiichi Ohno from Toyota. What he created went on to become the Toyota Production System (TPS).

The TPS was focused on eliminating waste from the manufacturing process.

In business, it means eliminating or reducing waste from any system or process that doesn’t add value to your customer (“waste”).

Let’s take a look at 7 “waste” areas that MAY be affecting YOUR business (and your customers!). And remember, waste often disguises itself as productivity so keep your eyes peeled!

- Inventory

By this I mean too much inventory. “Just-in-case” stock, can be important to mitigate production delays or low quality. However, too much inventory increases storage needs and ties up cash flow.

In an office sense, this could be an inventory of projects that you have started and haven’t finished (WIP or work in process). Remember, busy doesn’t always mean effective, only manage what is possible, finish a project before adding another to your bucket, don’t let your bucket overflow.

- Waiting

When goods or tasks are not moving, “waiting waste” occurs, and this is easily recognizable as goods awaiting delivery, equipment waiting to be fixed, waiting for approvals or waiting for information.

- Defects

Defects cause rework, and don’t we hate re-doing something we have already done?! Not to mention it costs us money! Even worse, there may be no coming back from it – the product may end up in the bin. Checklists are key!

- Overproduction

Overproduction triggers the other 6 wastes to occur. Overproduction is producing more than the customer is willing to pay for. This can often be triggered by perfectionism!

For creatives, another way to look at this is, if ideas are produced too early they can often be obsolete by the time they’re needed.

- Motion

This means movements of workers or machinery that are complicated or unnecessary and can lead to injuries or missed deadlines.

In the office, this could also be mental motion. What’s the most common motion in the office? Looking for files! We can’t find what we need, we get distracted by something else on the journey and before we know it, we are down a rabbit hole and have completely forgotten what we started out to do.

- Transportation

Moving resources or materials, when the movement doesn’t add value to the product can be costly to your business and potentially damage the quality.

In an office, transportation of information often equals emails. Send complete thoughts, as a brief or quick response may lead to many more emails going backwards and forwards to clarify. Make sure your quick response doesn’t start a game of email ping pong. Conversely, don’t write an email novel with no point.

- Over-processing

This is doing work that doesn’t bring additional value or that brings more value than what the customer is willing to pay for. Adding features no one will use only increases your costs.

Multitasking fits in here as humans can’t multitask – it only leads to mistakes and reduces efficiency.

Sometimes “Lean” can be overwhelming to start, so start small. Making small improvements every day adds up to big improvements over time. And never stop, there is always more to do!

Amber is the owner of PUTTY. Check out how Amber’s team helps their clients wrangle their systems and tech HERE.

Print This Post

Print This Post